| BMW Garage | BMW Meets | Register | Today's Posts | Search |

|

|

|

SUPPORT ZPOST BY DOING YOUR TIRERACK SHOPPING FROM THIS BANNER, THANKS! |

|||||||||

Post Reply |

|

|

Thread Tools | Search this Thread |

| 04-24-2014, 05:03 PM | #23 | |

|

Major

74

Rep 1,143

Posts |

Quote:

The criticism about not designing for maintainability is fair but from the business perspective, likely don't impact their current target audience. The Model S is designed and priced to be bought by relatively affluent individuals who are probably not gearheads (who would more likely buy M3s, Porsches, Corvettes, etc.) I doubt there will be many Tesla owners who try to service their vehicles at home, and they can likely afford having it serviced professionally down the road. Having worked with both Tesla and SpaceX as a supplier I can definitely attest to some aspects of their organization being run pretty poorly. At the same time, I think it's pretty incredible that such a small company has been able to pull off a product that's as good as it is even with the faults you mentioned. |

|

|

Appreciate

0

|

| 04-24-2014, 05:13 PM | #24 |

|

Colonel

1567

Rep 2,665

Posts |

Interesting information about Tesla but without evidence of failures (and failure rates) it seems like the opinion above is they should have designed it differently and it is expected there will be problems but no proof of anything. Any proof of problems associated with the above?

__________________

2006 Z4M Coupe - Stromung exhaust, ZHP knob, stubby antenna, clutch delay delete

|

|

Appreciate

0

|

| 04-25-2014, 09:44 AM | #25 | |

|

Mechanical Engineer

96

Rep 1,025

Posts |

Quote:

The frustration will appear in 3 or 4 years when the maintenance comes due. |

|

|

Appreciate

0

|

| 04-26-2014, 07:34 PM | #26 | |

|

Colonel

1567

Rep 2,665

Posts |

Quote:

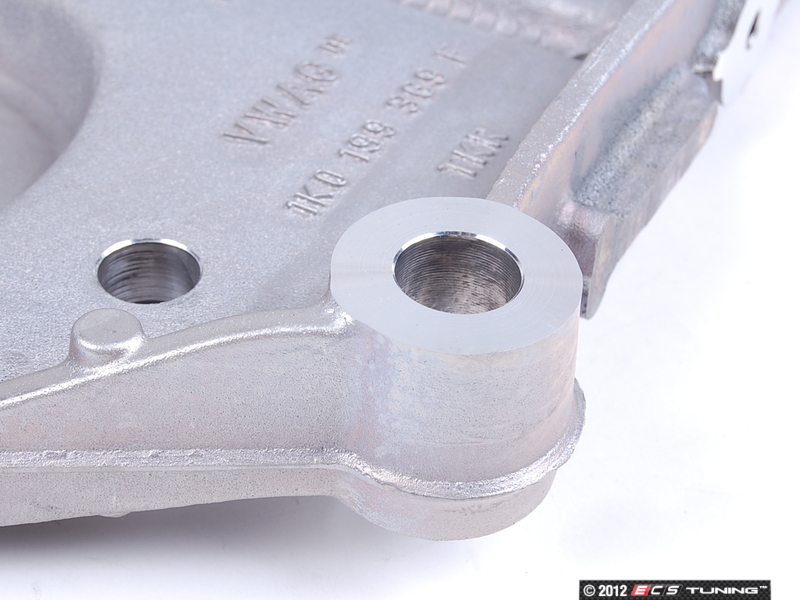

[IMG]  Subframe by dmorrowzzz, on Flickr[/IMG] Subframe by dmorrowzzz, on Flickr[/IMG][IMG]  Subframe1 by dmorrowzzz, on Flickr[/IMG] Subframe1 by dmorrowzzz, on Flickr[/IMG]

__________________

2006 Z4M Coupe - Stromung exhaust, ZHP knob, stubby antenna, clutch delay delete

|

|

|

Appreciate

0

|

| 04-29-2014, 10:08 PM | #27 |

|

Private First Class

19

Rep 196

Posts |

I see your point about tapped aluminum, but to play devils advocate... Isn't the point to prove to the public just how far you can go in an all electric car today? Not about tomorrow or how long you can own the car for. By eliminating the nuts, they are pulling out as much weight as they can without entering into cost prohibitive exotic materials.

I know we can't applying Moore's Law to electric vehicles here, but once the energy storage problem takes it's next leap forwards, aren't these cars going to become obsolete for the customer base they are targeting? What does interest me in what you've observed is did you see if the quick-swap battery bolts are also tapped aluminum? One extra question. I'm not an engineer, but do electric motors require bushings? My understanding is they serve to isolate the vibration of an engine from the body, but a motor is usually balanced and spins at much faster rates. Are they comparable between gas and electric?

__________________

Last edited by sipman; 04-29-2014 at 10:18 PM.. |

|

Appreciate

0

|

| 04-30-2014, 07:43 AM | #28 |

|

Mechanical Engineer

96

Rep 1,025

Posts |

Sipman, I think you're right, that may be what they were going for, but I still disagree with them that it was the right choice. Eliminating all the nuts on the car is probably only 2 to 3 pounds; hardly worth the high cost of repairs down the road. And if it was really about weight savings, they could have used a t-nut style drop in insert; same amount of frame material is removed, but the threaded portion is replaceable.

I did not see the bottom of the chassis, it was sitting on the floor, rather than on a display lift. I really hope they were at least smart enough not to put those bolts into tapped aluminum. That could suddenly turn your 60 second battery swap into a 3 hour repair. For the bushings, two ways of thinking on the electric/gas question. Yes, electric motors generally vibrate less, so its reasonable to assume they need less/smaller bushings. However, think about all of the bushings on a Z4. Only 4 (ish?) of them are connected to the engine/transmission, the rest of them are part of the suspension. The need to isolate the body/frame from the suspension isn't going to change much going from a gas to an electric engine, so the majority of the bushings are going to be unaffected by that. Second way of thinking, yes, they vibrate less, but they also have much less rotating inertia, and so will be spun up to speed and down to idle a lot more often. So, less constant, low level vibration, but a lot more high torque shocks to the mounts and drive train as the motor goes from idle to high speed very quickly. I thought that the electric motors on the tesla were mounted with bushings, but I'm not 100% sure. They're sort of trapped in a cage at the rear of the car formed by the chassis and the subframe, the bushings I saw in that area could be either motor mounts or subframe bushings. For the energy storage problem, you're right, if battery technology suddenly takes a 10X leap forward, all of the electric cars on the road, maybe even all cars on the road, will suddenly be obsolete. However, since lithium ion batteries were introduced commercially in the 90s, there hasn't been more than a 50% increase in the energy density (watt-hours per pound) of commercially viable batteries (and I think I'm way overestimating that at 50%, its probably more like 20%). Energy storage density is a hugely difficult problem, one that gets a ton of R&D money and still isn't progressing very fast, so I don't think we can expect any major progress on that area any time soon. |

|

Appreciate

0

|

Post Reply |

| Bookmarks |

|

|